[ad_1]

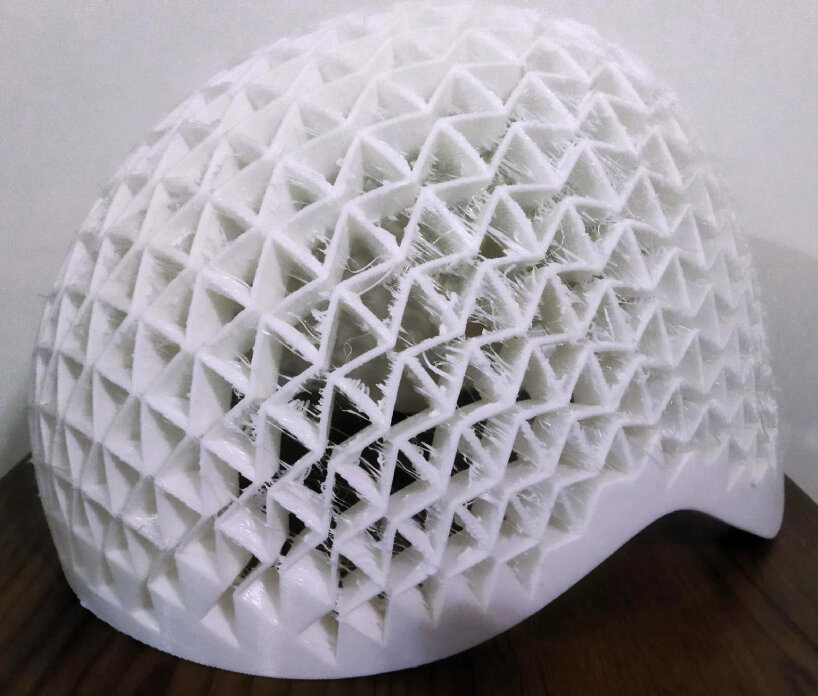

3D printed bike helmet by Universities of Gothenburg and Isfahan

Researchers at the Universities of Gothenburg and Isfahan have developed a 3D printed bike helmet that protects the head by contracting during accidents. The shock-absorbing, plastic-based material contracts bilaterally. In this way, the energy of the impact dissipates during collisions. The researchers say that traditional bicycle helmets rely on foam liners for impact absorption. These, however, have limitations in terms of fit and effectiveness.

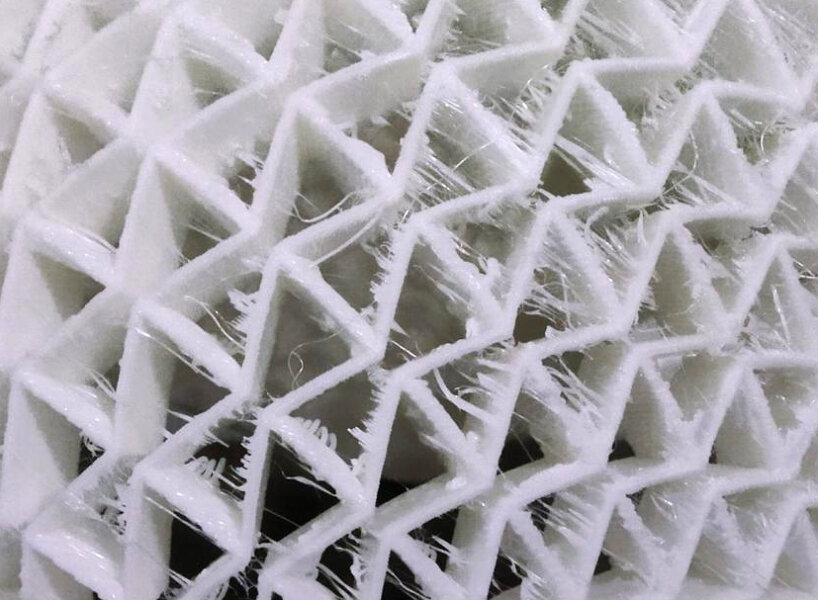

The 3D printed bike helmet incorporates auxetic metastructures. These are the geometric patterns that respond differently to impact compared to conventional materials and to the typical honeycomb style. Mohsen Mirkhalaf, Associate Professor at the University of Gothenburg and researcher of the study, says that when exposed to energy from an impact, the liner material contracts, improving impact absorption and reducing the risk of head injuries.

all images courtesy of the researchers at Universities of Gothenburg and Isfahan

helmet’s protective layer uses hyperelastic polymer

The research study, published in the International Journal of Solids and Structures, explores the use of auxetic metastructures, computer simulations, and optimization techniques to develop a safer, 3D printed bike helmet. The researchers at the Universities of Gothenburg and Isfahan focus on identifying the best geometric configuration to minimize crash forces. They emphasize the importance of material structure to absorb the crash impact. To test this concept, they 3D print the helmet’s protective layer using a hyperelastic polymer.

This plastic material is capable of significant deformation while returning to its original shape. This makes it durable enough to withstand impact. So far, the researchers have conducted standard impact tests on the new 3D printed bike helmet. During the phase, they have evaluated the gear’s performance against two different types of collisions. The results show that the design provided improved head protection compared to conventional helmets, showing the potential of auxetic metastructures for future helmets.

the 3D printed bike helmet incorporates auxetic metastructures, which respond differently to impact

auxetic metastructures for other impact-protection gear

The researchers believe that studies on auxetic metastructures, which expand laterally when stretched, have advanced significantly because of the developments in 3D printing technology. While this concept has been known for nearly 40 years, recent innovations allow them to experiment with more efficient design. Their 3D printed bike helmet is lighter, plus the auxetic liner can also be customized to fit individual head shapes using 3D printing. This makes it particularly ideal for athletes or individuals who struggle to find a fitting helmet.

Although current production costs for 3D printed liners, including those for bike helmets, are higher than mass-produced foam liners, the researchers say these costs may decrease as the technology becomes more widespread. In the future, on-demand printing can even allow for personalized helmets. This research represents a step toward smarter protective equipment, with potential applications beyond cycling. The same technology could be adapted for other activities that require impact protection, including gears and pads.

the researchers print the helmet’s protective layer using a hyperelastic polymer

the plastic material is capable of significant deformation while returning to its original shape

when exposed to energy from an impact, the liner material contracts

project info:

name: 3D printed bike helmet

institutions: University of Gothenburg, University of Isfahan | @universityofgothenburg, @university_isfahan

researchers: Mohammad Hossein Zamani, Mohammad Heidari-Rarani, Mohsen Mirkhalf

[ad_2]

Source link